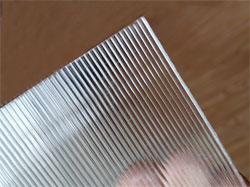

52LPI 2mm thickness plastic 3d lenticular board sheet 3d lens

Product Name:

52LPI 2mm thickness plastic 3d lenticular board sheet 3d lensModel No.:

YW3D2540/3d lenticularPrice:

55Minimum Order:

30

Product Abstract:

52LPI 2mm thickness plastic 3d lenticular board sheet 3d lens-3d lenticular-3d lenticular

- Product Description

52LPI 2mm thickness plastic 3d lenticular board sheet 3d lens

We make all lenticular,and we only make lenticular,we are professional in lenticular.LenticularMobi.

22LPI plastic 3d lenticular board sheet 3d plate Lenticular plates, Manufacturer

22LPI 4.8mm thickness plastic 3d lenticular board sheet 3d lens Lenticular plates, Manufacturer

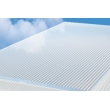

1. Lenticular plates

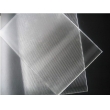

Lenticular plates, namely cylindrical lens lenticular plates, emerged in 1930. It's made of PS ( polystyrene ) plates or Acrylic plates, with strong third dimension, high transparency, water proof , resisting against chemical corrosion

2. The features of lenticular plate

The plate is easy to color, odorless, tasteless and nontoxic. It's rigid, insulative, and high transparent and photic, light in weight, strong break-resistant, high mechanical strength and toughness, heat-resistant, aging-resistant, also resistant to organic acid, alkali, salt and lower alcohols.

3. The uses of lenticular plates

The lenticular plates which focus strongly, simple producing technics, far sight distance, strong third dimension, are widely used to make all kinds of 3D decorating pictures in hotels, restaurants, shopping malls, stadiums, airport terminals, shelters ,wedding dress studios, figure portrait, it's also used to make indoor and outdoor light box ads and large posters etc.

4. The types of 3D lenticular plates

Lenticular plates, Manufacturer

Our Lenticular Material Products:

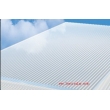

Lenticular lens sheet:3d lenticular board and lenticular sheet.

lenticular board plastic 3d plate:10LPI,12LPI,15LPI,16LPI,18LPI,20LPI,22LPI,25LPI,30LPI,32LPI,40LPI,42LPI,50LPI,53LPI,60LPI

lenticular lens plastic 3d sheets:40LPI.50LPI,59LPI,70LPI,75LPI,76LPI,80LPI,85LPI,90LPI,100LPI,150LPI,161LPI,200LPI

For more information,please visit http://www.ppoo.com or send an email to 3d@lenticular.mobi

5.The parameters of 22LPI Lenticular plates

22LPI 4.8mm thickness plastic 3d lenticular board sheet 3d lens

lenticular board,Lenticular morphing effects,lenticulars,Hebi Henan Lenticular,3d lenticular bookmark.3D Fourier transform,300 LPI Lenticular,

52LPI 2mm thickness plastic 3d lenticular board sheet 3d lens

Lenticular board:10LPI,12LPI,15LPI,16LPI,18LPI,20LPI,22LPI,24LPI,25LPI,30LPI,32LPI,40LPI,42LPI,50LPI,53LPI,60LPI,62LPI,64LPI

Lenticular sheets:40LPI,50LPI,59LPI,60LPI,70LPI,75LPI,80LPI,85LPI,90LPI,100LPI,150LPI.160LPI,161LPI,200LPILenticular lens sheet pricelist: http://www.ppoo.com/lenticular-price.pdf

3d lenticular price,board PS

High quality'Green and Save lenticular material.

Shanghai 3D printing,lenticular Importers.What is the principle of 3D Lenticular painting,42LPI lenticular sheet,3d lenticular placemat,3D painting Lenticular,

52LPI 2mm thickness plastic 3d lenticular board sheet 3d lensPost-guide to graphic mounting

Photo mounting depends on the stability of the machine itself on one hand, but more importantly lies in the user's operating skills. In view of the general use of simple cold mounting machine, we introduce several methods of operation for your reference:

1.Wiping the grating plate with a clean cloth and cutting a double-sided adhesive tape (double-sided adhesive tape is larger than the grating sheet). Turning the pressure-regulating handle of the boxes on both sides of the machine, then separating the upper axle from the lower axle and placing the grating and double-sided adhesive into the two rollers in-between (the double-sided adhesive is put on the smooth side of lenticular lens sheet, if the two sides is transparent, then omit this step), rotating the pressure-handle to moving down the upper axle parallelly until the regulator handle is very tightly (Note: the pressure must be balanced, otherwise it easily leads to bubbles. The pressure should be medium, if too big or too small, problems will come).

2. After adjusting the pressure well, we turn cold mounting roller to make this side close to the operation a little spare space, then picking up the double-sided adhesive and folding down isolation paper or film, and film encases cold mounted roller and (focus) rotate it to make this part adhesive to the grating. Making the sticky side in front and pressing into the two rollers in -between of the cold mounted machine. Picking up the double-sided adhesive paper to tear away all of the remaining isolation paper. Adhesive film encase cold mounted roller (focus), turning rollers of cold mounting (try not to stop in the middle). Thus this side is mounted well, with the blade to cut the abundant part. The other side is mounted well like that.

3. Putting the picture on the table and cutting a small portion of the isolation film on the grating sheet (attention: not too much). Covering the paintings with grating sheet, closing one eye with one hand pulling thelenticular lens until the objects in the picture moving left and right as a whole, rather than up and down or sub-section . (if the picture need to be installed into the frame, just hit the black lines on the edge of the screen). Press tightly and do not let the lenticular lens move, put down that part of thelenticular lens without membrane and stick well (first stick to the middle, then drive to the sides from up - down). That sticky side is in front and press it into the two rollers in-between of the cold mounting machine . Pick up the grating and tear away all the remaining membrane, lenticular lens encases cold mounting roller (focus) turned cold mounting roller, thus a picture will be mounted well.lenticular technology limited2017/1/10 20:36:29

- Related Products

- [Return Home] [Print] [Go Back]

Products Search

Contact Us

Contact Person:

Ms.ElaineTel:

0086-13136538608Fax:

E-mail:

sales@ppoo.com-