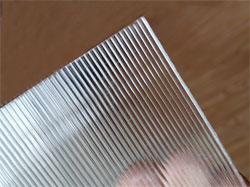

Best Quality 50LPI Lenticular Mould design for Inkjet/UV Flatbed Printer

Product Name:

Best Quality 50LPI Lenticular Mould design for Inkjet/UV Flatbed PrinterModel No.:

Lenticular Mobi11915/LenticularPrice:

40Minimum Order:

60

Product Abstract:

Best Quality 50LPI Lenticular Mould design for Inkjet/UV Flatbed Printer-Lenticular-Lenticular

- Product Description

Best Quality 50LPI Lenticular Mould design for Inkjet/UV Flatbed Printer

Lenticular painting production equipment.3D Lenticular material,lenticular Importers,Guangdong 3D printing company ranking,3D printing technology principle,

Popular Lenticular Lens Material Introduction:30LPI 3mm thickness plastic 3d lenticular board sheet 3d plate lens

30LPI 3mm thickness plastic 3d lenticular board sheet 3d plate lens1. Lenticular plates

Lenticular plates, namely cylindrical lens lenticular plates, emerged in 1930. It's made of PS ( polystyrene ) plates or Acrylic plates, with strong third dimension, high transparency, water proof , resisting against chemical corrosion

2. The features of lenticular plate

The plate is easy to color, odorless, tasteless and nontoxic. It's rigid, insulative, and high transparent and photic, light in weight, strong break-resistant, high mechanical strength and toughness, heat-resistant, aging-resistant, also resistant to organic acid, alkali, salt and lower alcohols.30,30LPI

3. The uses of lenticular plates:

The lenticular plates which focus strongly, simple producing technics, far sight distance, strong third dimension, are widely used to make all kinds of 3D decorating pictures in hotels, restaurants, shopping malls, stadiums, airport terminals, shelters ,wedding dress studios, figure portrait, it's also used to make indoor and outdoor light box ads and large posters etc.

4. The types of 30LPI lenticular plates:

At present, there are five kinds of lenticular plates: 18LPI, 25LPI, 32LPI, 42LPI, 53LPI.30LPI

5. The parameters of 32LPI lenticular plates

Specification: 1200*2400 *3mm

Sight stripes

Sight angle: 39°

Sight distance:1.5_8m

The best sight distance: 3 m

lenticular print,lenticular 3d picture,Concave convex concave Lenticular plate,3D painting Lenticular material factory,

Best Quality 50LPI Lenticular Mould design for Inkjet/UV Flatbed Printer

Lenticular board:10LPI,12LPI,15LPI,16LPI,18LPI,20LPI,22LPI,24LPI,25LPI,30LPI,32LPI,40LPI,42LPI,50LPI,53LPI,60LPI,62LPI,64LPI

Lenticular sheets:40LPI,50LPI,59LPI,60LPI,70LPI,75LPI,80LPI,85LPI,90LPI,100LPI,150LPI.160LPI,161LPI,200LPILenticular lens sheet pricelist: http://www.ppoo.com/lenticular-price.pdf

Lenticular Beijing,Mould Zhengzhou

High quality'Green and Save lenticular material.

We make all lenticular,and we only make lenticular,we are professional in lenticular.LenticularMobi.516

Best Quality 50LPI Lenticular Mould design for Inkjet/UV Flatbed PrinterLenticular FAQ: 2D to 3D Conversions If you need a 2D image converting to 3D, then that’s a snip too. Rather than using software to generate a 3D effect that can look like flat plains in space, like a pantomime set, we use traditional techniques with the human eye and hand, giving roundness to objects that should look round, and depth where you expect depth. It is the closest we have got to ‘Real 3D’ and pride ourselves on the quality of this output. We can usually convert a 2D image to 3D in 24 to 48 hours dependant on complexity .

Lenticular Sheets Technology Limited2017/1/15 19:03:42

- Related Products

- [Return Home] [Print] [Go Back]

Products Search

Contact Us

Contact Person:

Ms.ElaineTel:

0086-13136538608Fax:

E-mail:

sales@ppoo.com-