Plastic 3D Lens,Good Quality Special Lighting Plastic

Product Name:

Plastic 3D Lens,Good Quality Special Lighting PlasticModel No.:

YW3D-4020/Lenticular sheetsPrice:

Plastic 3D Lens FranceMinimum Order:

80

Product Abstract:

Plastic 3D Lens,Good Quality Special Lighting Plastic-Plastic 3D Lens-Lenticular.mobi-Plastic 3D Lens best91660

- Product Description

Plastic 3D Lens,Good Quality Special Lighting Plastic86281

We make all lenticular,and we only make lenticular,we are professional in lenticular.LenticularMobi4795

Lenticular Sheets information like Material/LPI/Thickness/Standard Size/Weight/Packing pallet/MOQ/Viewing Angel/Effects For/Printer/Software/Price/Unit,

Please check: http://www.ppoo.com/lenticular-price.pdf

If any other question,please email to 3d@lenticular.mobiPlastic 3D Lens,Good Quality Special Lighting Plastic

Plastic 3D Lens,Good Quality Special Lighting Plastic

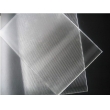

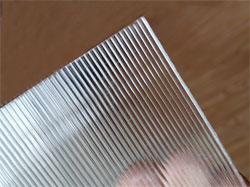

40LPI lenticular sheets for 3d lenticular printing. 40LPI 2mm 40LPI plastic lenticular lens sheet,best for strong 3d effects large format posters, Hot tags: lenticular sheet,Lenticular Exporters,Lenticular manufacturers,Lenticular factory,Lenticular Suppliers,Lenticular array,Lenticular Importers,3d lenticular,3d lenticular printing service,3d lenticular design,Lenticular.

Brand:YW3D

Printed By:inkjet/uv flatbed printer

Effects:best for 3D

Viewing Angel:45degree

Pricelist:http://www.ppoo.com/lenticular-price.pdf

Tag:40LPI lenticular sheet,lenticular lens,lenticular plate

Application:best for 3d effects large format lenticular products

Stability:High stability/Uniform LPI number

Quality:High quality&Green&Safe

Thickness:2mm

3d lenticular pictures 3D Photo,lenticular technology 3D Lenticular Folder,25 LPI 3D Lenticular plate,for 3d lenticular printing 3D Postcard.

Color:transparent

Standard Size:W1.2*H2.4m/Line length is 2.4m

LPI:40

Packing:wooden pallet,save packing

Material:PS plastic

We can cut sheet based on requirements and customized.

Delievery time:1-5 days

10~60LPI For inkjet printer and uv flated printer,

70LPI~200LPI For offset printer. 6127Many kinds of lenticular material, how to choose?

You can consider belows:Thickness;Visual angle ;Which product do you want to make?Future size of your lenticular products;Where do you put?for example: hold in the hand, or hang on the wall;What effect do you want to design? 3D or flip or other effects?What is your observation distance ? 0.5m? Or 1m? Or others?What is your printing machine? offset printing press or inkjet printer or UV flatbed printer?Hebi Henan Lenticular.3d lenticular printing lenticular soft printing.

Plastic 3D Lens,Good Quality Special Lighting Plastic

Quality PP,Lighting Shenzhen Plastic 3D LensPlastic 3D Lens

Weight:6.8KG/PCS

Plastic 3D Lens,Good Quality Special Lighting PlasticLenticular Relevant:

Post-guide to graphic mounting

Photo mounting depends on the stability of the machine itself on one hand, but more importantly lies in the user's operating skills. In view of the general use of simple cold mounting machine, we introduce several methods of operation for your reference:

1.Wiping the grating plate with a clean cloth and cutting a double-sided adhesive tape (double-sided adhesive tape is larger than the grating sheet). Turning the pressure-regulating handle of the boxes on both sides of the machine, then separating the upper axle from the lower axle and placing the grating and double-sided adhesive into the two rollers in-between (the double-sided adhesive is put on the smooth side of lenticular lens sheet, if the two sides is transparent, then omit this step), rotating the pressure-handle to moving down the upper axle parallelly until the regulator handle is very tightly (Note: the pressure must be balanced, otherwise it easily leads to bubbles. The pressure should be medium, if too big or too small, problems will come).

2. After adjusting the pressure well, we turn cold mounting roller to make this side close to the operation a little spare space, then picking up the double-sided adhesive and folding down isolation paper or film, and film encases cold mounted roller and (focus) rotate it to make this part adhesive to the grating. Making the sticky side in front and pressing into the two rollers in -between of the cold mounted machine. Picking up the double-sided adhesive paper to tear away all of the remaining isolation paper. Adhesive film encase cold mounted roller (focus), turning rollers of cold mounting (try not to stop in the middle). Thus this side is mounted well, with the blade to cut the abundant part. The other side is mounted well like that.

3. Putting the picture on the table and cutting a small portion of the isolation film on the grating sheet (attention: not too much). Covering the paintings with grating sheet, closing one eye with one hand pulling thelenticular lens until the objects in the picture moving left and right as a whole, rather than up and down or sub-section . (if the picture need to be installed into the frame, just hit the black lines on the edge of the screen). Press tightly and do not let the lenticular lens move, put down that part of thelenticular lens without membrane and stick well (first stick to the middle, then drive to the sides from up - down). That sticky side is in front and press it into the two rollers in-between of the cold mounting machine . Pick up the grating and tear away all the remaining membrane, lenticular lens encases cold mounting roller (focus) turned cold mounting roller, thus a picture will be mounted well.Lenticular Sheets Technology Limited2017/3/27 20:21:15

Plastic 3D Lens,Good Quality Special Lighting Plastic

- Related Products

- [Return Home] [Print] [Go Back]

Products Search

Contact Us

Contact Person:

Ms.ElaineTel:

0086-13136538608Fax:

E-mail:

sales@ppoo.com-