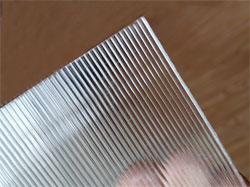

Wholesale 10LPI Lenticular Sheet for UV flatbed printer

Product Name:

Wholesale 10LPI Lenticular Sheet for UV flatbed printerModel No.:

Lenticular Mobi18741/LenticularPrice:

54Minimum Order:

60

Product Abstract:

Wholesale 10LPI Lenticular Sheet for UV flatbed printer-Lenticular-Lenticular

- Product Description

Wholesale 10LPI Lenticular Sheet for UV flatbed printer

We make all lenticular,and we only make lenticular,we are professional in lenticular.LenticularMobi.228

Popular Lenticular Lens Material Introduction:40LPI 2mm thickness plastic 3d lenticular board sheet 3d lens

The parameters of 40LPI lenticular plates:

Specification: 1200*2400 *2mm

Sight stripes

Sight angle: 45°

Sight distance:1_5m

The best sight distance: 2 m

Beijing 3D printing factory,3D Lenticular plate.lenticular plastic,70LPI lenticular lens,3D printing the first unit.plastic lenticular lenses,

Wholesale 10LPI Lenticular Sheet for UV flatbed printer

Lenticular board:10LPI,12LPI,15LPI,16LPI,18LPI,20LPI,22LPI,24LPI,25LPI,30LPI,32LPI,40LPI,42LPI,50LPI,53LPI,60LPI,62LPI,64LPI

Lenticular sheets:40LPI,50LPI,59LPI,60LPI,70LPI,75LPI,80LPI,85LPI,90LPI,100LPI,150LPI.160LPI,161LPI,200LPILenticular lens sheet pricelist: http://www.ppoo.com/lenticular-price.pdf

Lenticular company,print Zhejiang

High quality'Green and Save lenticular material.

3d sheet.Lenticular poster,

Wholesale 10LPI Lenticular Sheet for UV flatbed printerLenticular FAQ:

Printing lenticularThe RIP and CTP play a large role in the quality of a lenticular print. While average machines can produce an acceptable result, when the work is compared to another created using a higher resolution RIP and CTP, the differencebetween 2,400 dpi and 4,000 dpi image is exponential in the final product. When it comes to video lenticular, a higher resolution image allows for more video frames.

“The majority of commercial printers already have the minimum spec for commercial work. Very few own or upgrade for the high resolution because they’ve never had to,” says Clark. “I usually show printers both resolutions, apples to apples, and when they see the results, they make the upgrade to the higher resolution. The look is day and night, hands down, it’s not even close.” From plating, traditional printing craft takes over. The quality and consistency of a printer are crucial variables in lenticular printing.

Well-maintained presses, the newer the better, make or break the job. One reason lenticular printing has generally been in the hands of a few is that the best way of applying ink to lenticular is through a UV process due to instant curing. With non-UV applications, temperature control of the IR lamps is important to lessen flaring, which adds to waste.

Even then, completed lenticular sheets need to be stacked on short lifts to allow for even more drying once off press. Just coming into production are non-UV inks that adhere faster to lenticular sheets, which will allow printers who do not have a UV dedicated press to try their hand at lenticular without elaborate drying setups. Static is another factor which also contribute to the complexity in running a lenticular job.

Lenticular Sheets Technology Limited2017/1/25 13:12:37

- Related Products

- [Return Home] [Print] [Go Back]

Products Search

Contact Us

Contact Person:

Ms.ElaineTel:

0086-13136538608Fax:

E-mail:

sales@ppoo.com-